Linear Motor Actuator With Driver

Linear Motor Actuator With Driver

This actuator redefines precision and durability in automation systems. Designed with advanced closed-loop control between the driver and actuator, this actuator offers superior accuracy over time, outperforming traditional screw-type actuators.

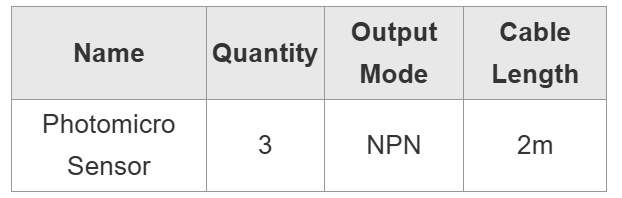

| Base Width (mm) | 82 |

| Type | Standard |

| Encoder | Incremental Magnetic Encoder |

| Number of Sliders (pcs) | 1 |

| Photo Micro Sensor Output Mode | NPN |

| Photo Micro Sensor Cable Length (mtr) | 2 |

| Compliance | RoHS10/CE |

What Will You Get

1. Linear actuator with one slider of selected stroke length

2. Misumi ETHER CAT driver with each actuator

What Else Will You Need

1) Extension Cable - as the default cable length of the Misumi EtherCat Driver is very small and you will definitely need to purchase the extension cable as per your requirement.

2) Drag Chain - for cable management/movement

2) Suitable Power Supply - as per your entire system configuration.

Demo Videos

Features

● Enhanced Longevity: With a lifespan up to 2.5 times longer than traditional screw-type actuators, these actuators ensures reliable and cost-effective performance.

● High-Speed Operation: Achieve speeds up to 4 times faster compared to traditional screw-type actuators with a lead of 10.

● Customizable Sliders: Featuring a single slider as standard, the design allows for customization to add or adjust the number of sliders based on your specific requirements.

● Reduced Noise Levels: Operates with noise levels up to 10% lower, ensuring quieter work environments even at high speeds.

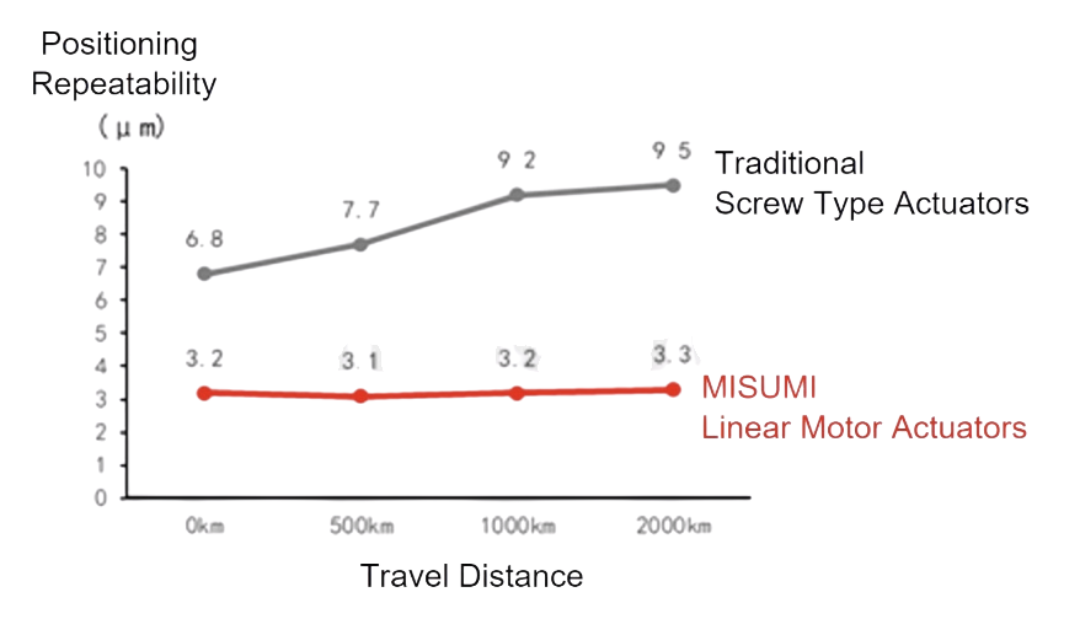

● Consistent Accuracy: Maintains precision and stability over long-term use, surpassing traditional actuators in reliability.

Product Overview

1) High Precision

- Positioning Repeatability is ±5μm

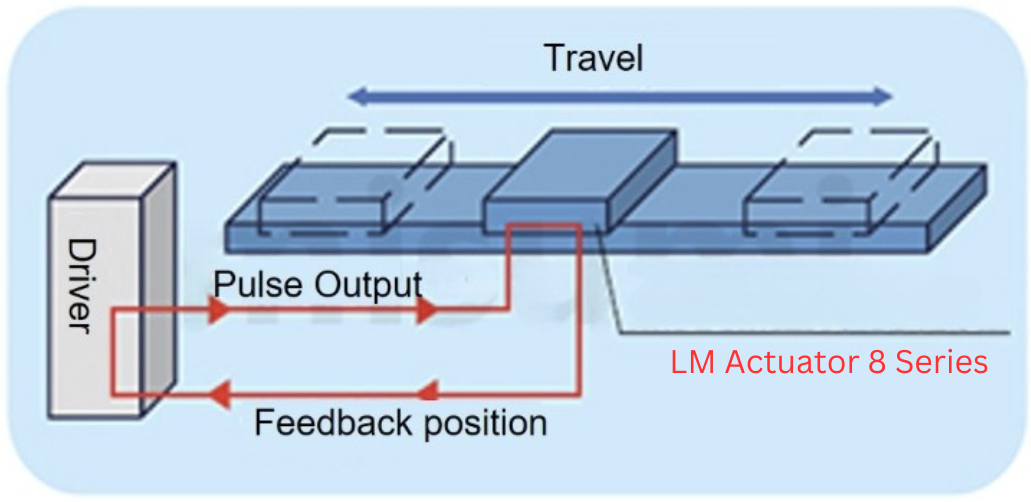

2) Closed Loop Control

- Linear Motor Actuator and Driver are closed-loop control, and the driver can compensate the current position in real time.

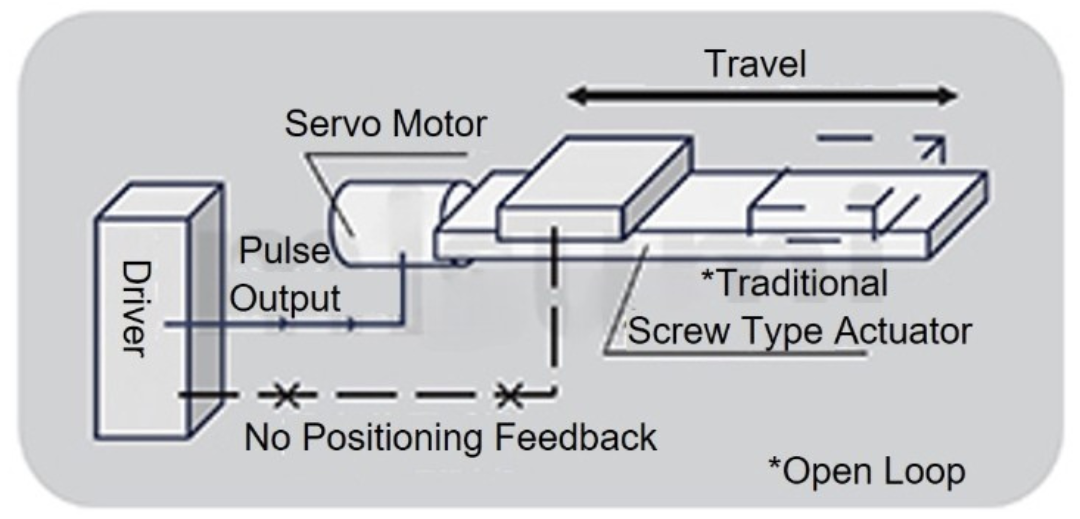

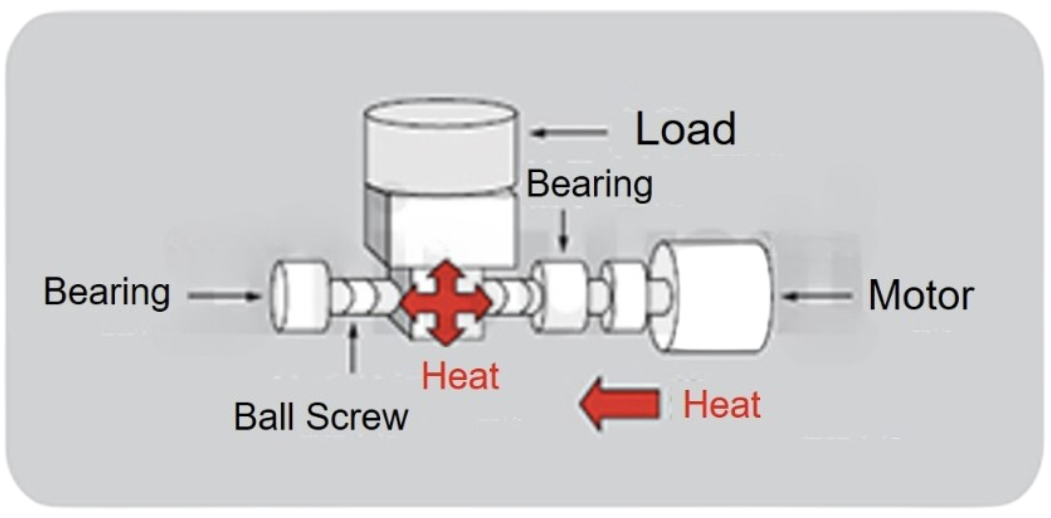

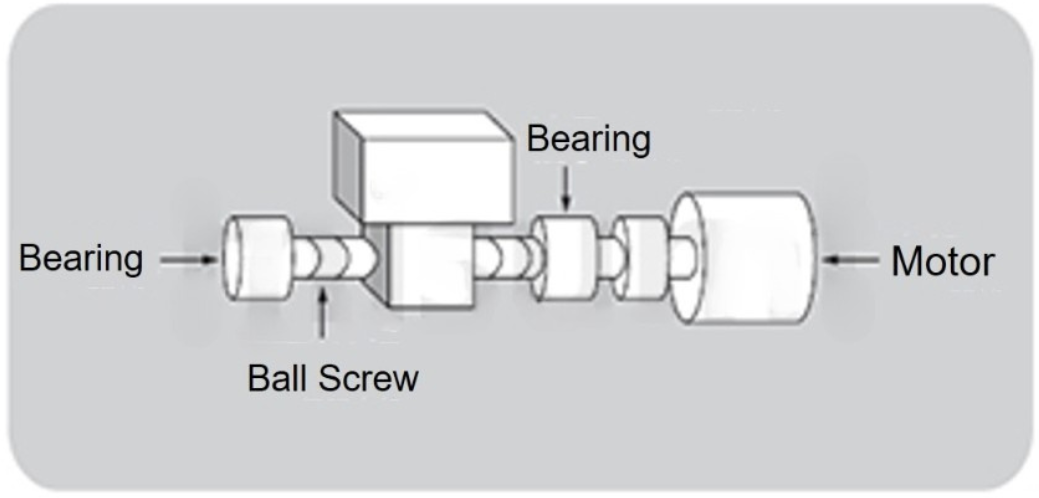

- Traditional Screw Type Actuators

- Motor driver and Traditional Screw Type Actuators are open-loop controls and cannot capture the current position with high precision.

3) High Speed

- Compared with the traditional screw type actuator with a lead of 10, the speed is increased by 4 times.

- At high speed, the noise is up to 10% lower than that of Traditional Screw Type Actuators*1

- Since the direct drive load, achieve high-speed operation 2.0m/s

- Traditional Screw Type Actuators

- Speed is limited by the screw lead. Resonance and heat generated at high speed

4) Long Lifetime

- Compared with Traditional Screw Type Actuators, lifetime up to 2.5 times better.

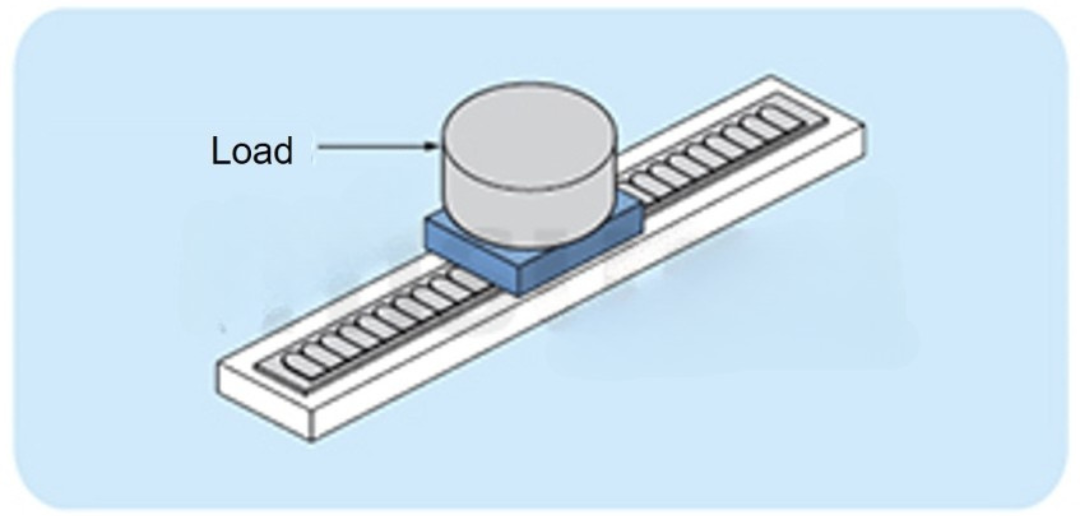

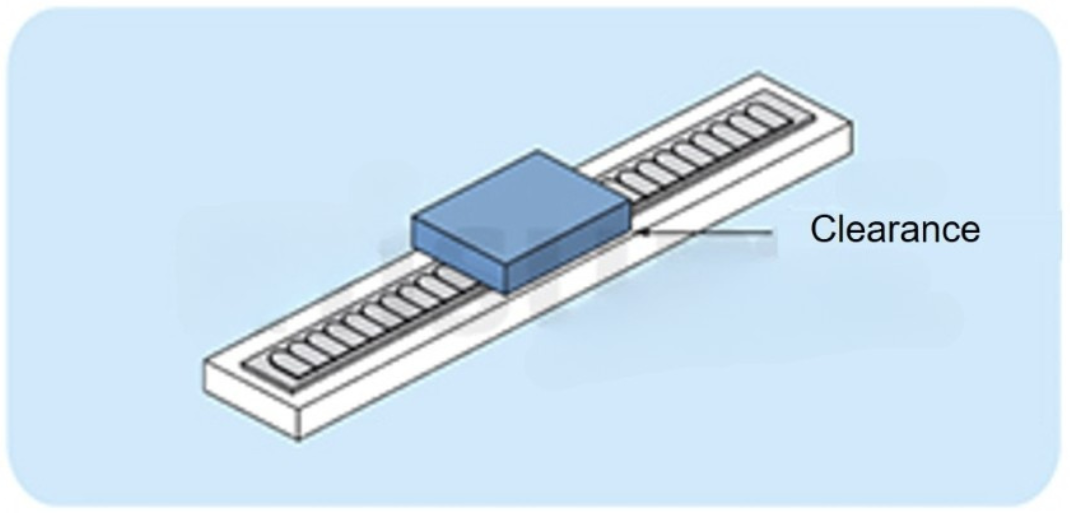

- No mechanical parts such as ball screws, bearings, couplings, etc.

- There is no direct contact between the slider and the magnetic track, maintenance-free life: 50,000 hours*2

- Traditional Screw Type Actuators

- Friction and wear occur due to the mechanical contacting parts. Regular maintenance also required.

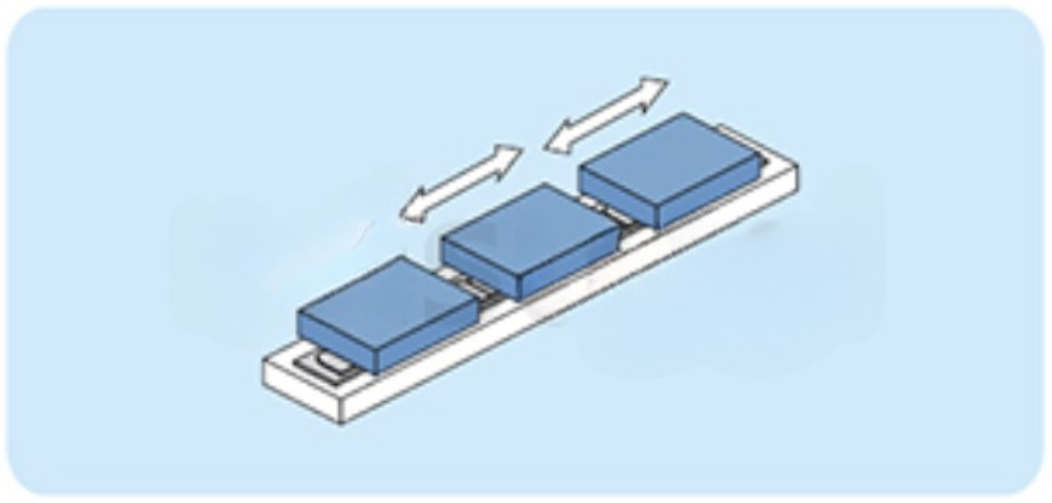

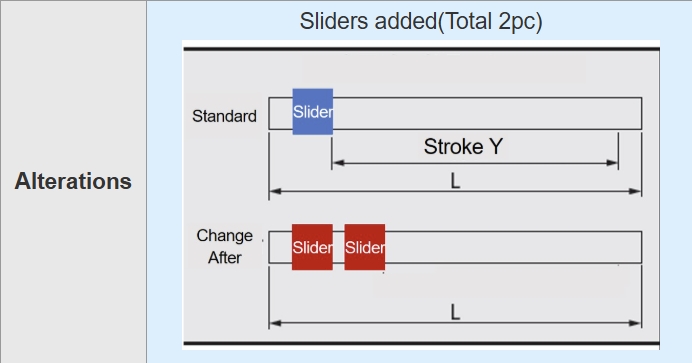

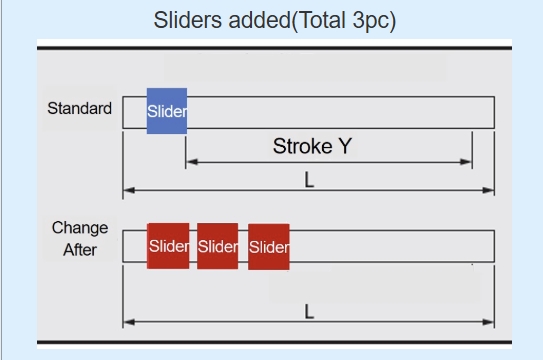

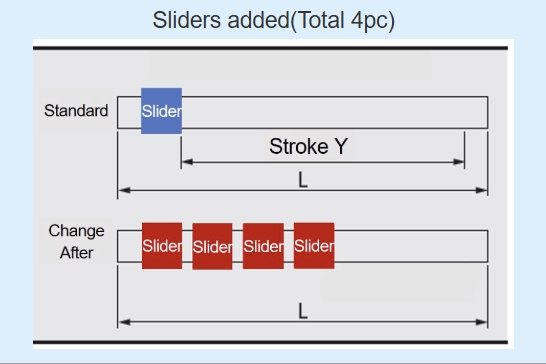

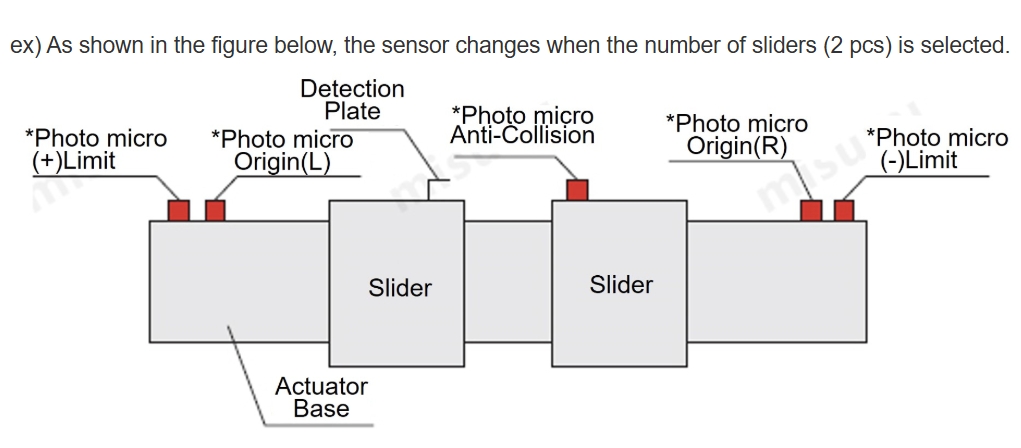

5) The number of sliders can be added on the same axis

- This actuator has a single slider and the number of sliders can be changed according to customers' requirements.

- Simple structure and low cost

- Can be controlled individually on the same module

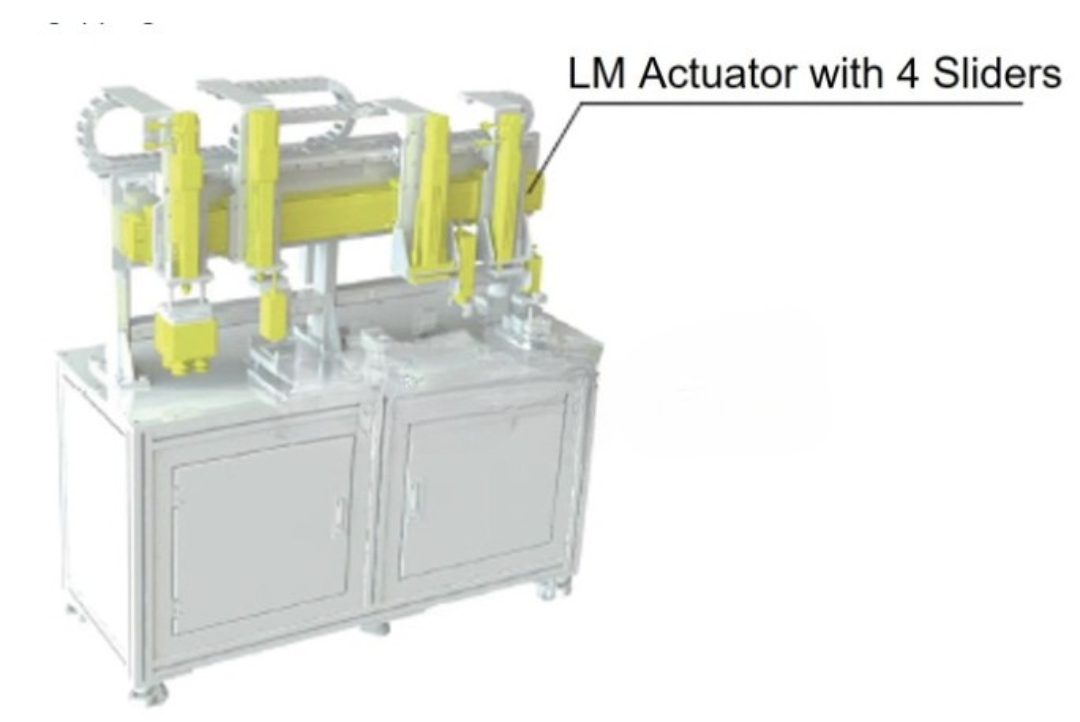

Usage example with multiple-Sliders

- The 4 Sliders can be controlled individually and cooperate with the electric cylinder and gripper to perform gripping actions.

Sliders Can Be Changed Up to 4 Sliders

After specifying the number of sliders, the number of photo micro sensors on the actuator base changes from 3 to 4, and the additional sliders will be equipped with an anti-collision photo micro sensor.

As shown in the figure below, the sensor changes when the number of sliders (2 pcs) is selected.

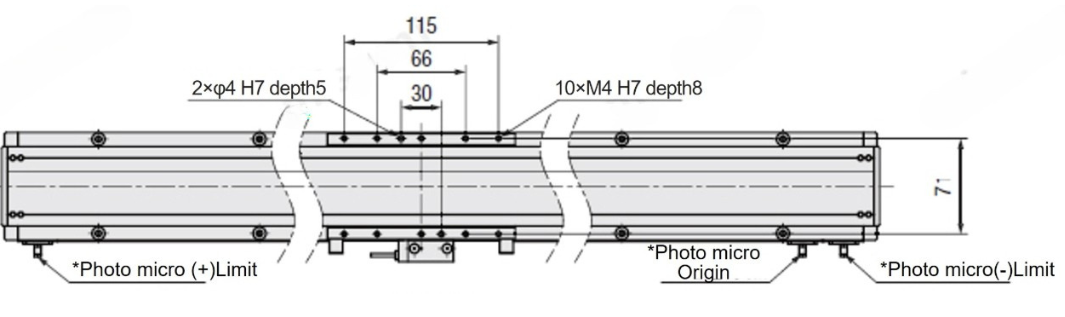

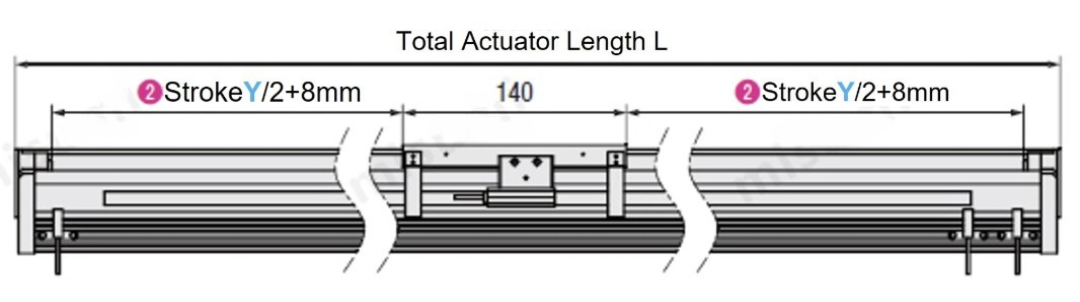

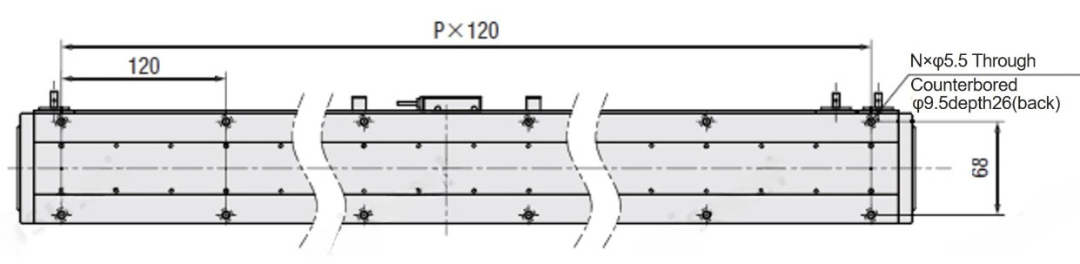

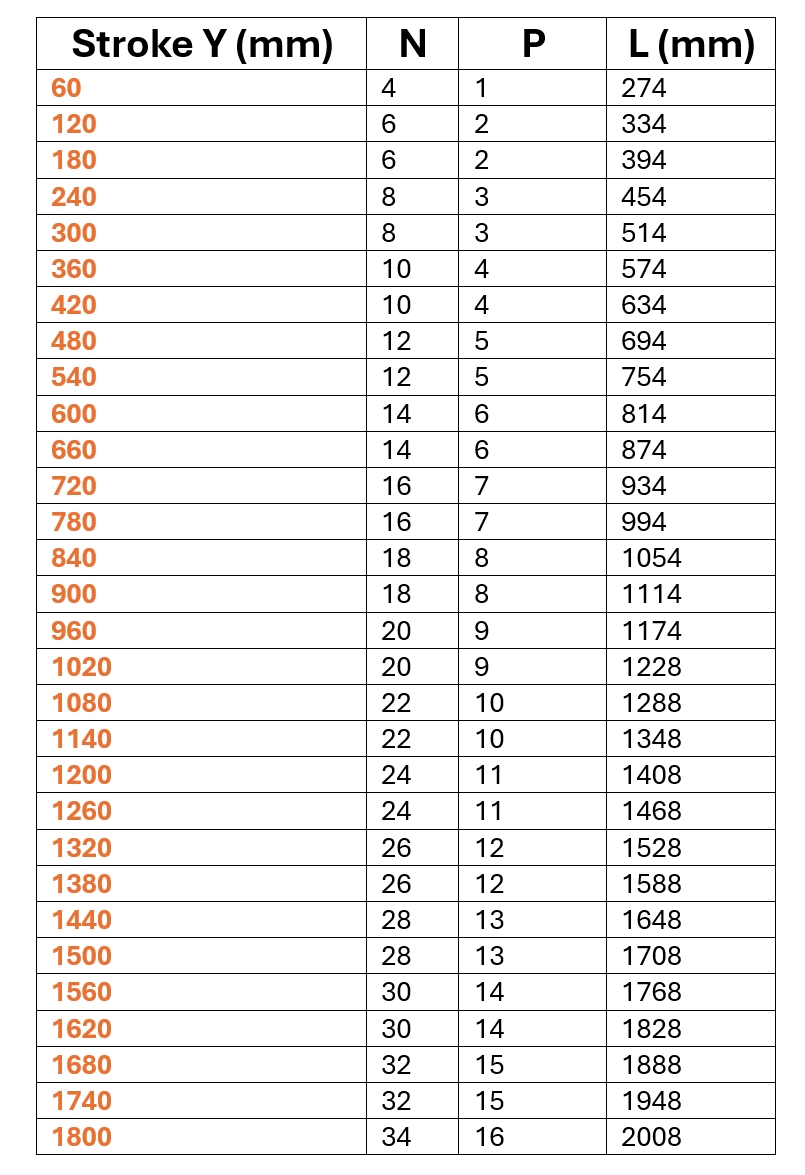

Dimensional Drawing

- Body

- Accessory

Please follow the selection steps ~

~ select the model and parameters to order

select the model and parameters to order

![]()

Type Type |

Stroke Y Stroke Y(Increment 60mm) |

Driver Driver |

Extension ExtensionCable Length |

Max Horizontal Load (kg) |

Max Vertical Load (kg) |

Continuous Thrust (N) |

Peak Thrust (N) |

Rated Speed (m/s) |

Max. Speed (m/s) |

Max. Acceleration & Deceleration (G) |

Positioning Repeatability* (μm) |

Number of Sliders (pcs) |

Straightness (mm/ 300mm) |

| E-RAM8-S | 60~1800 | If Self Provided Then Select - N | If Self Provided Then Select - N | 20 | 13 | 52 | 208 | 1.5 | 2.0 | 1.5 | Plus Minus 5 microns | 1 | Plus Minus 0.01 |

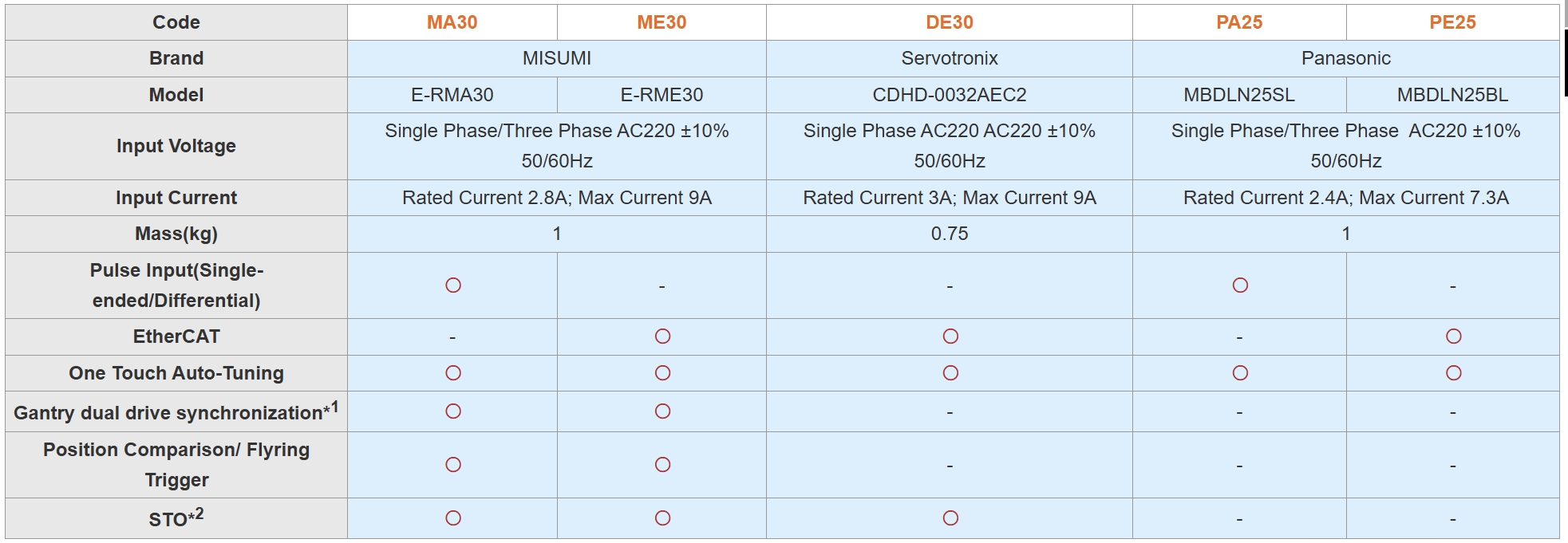

Drivers Which Can Be Used With This Actuator

1) Misumi Driver - E-RMA & E-RME - Click here for manual & all other documentation

2) Servotronix Driver - Click here for manual & all other documentation

3) Panasonic Driver - Click here for manual & all other documentation

Driver Details

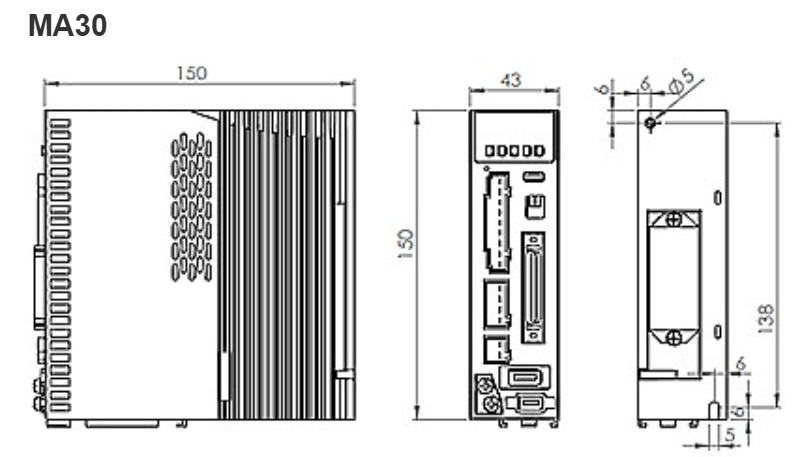

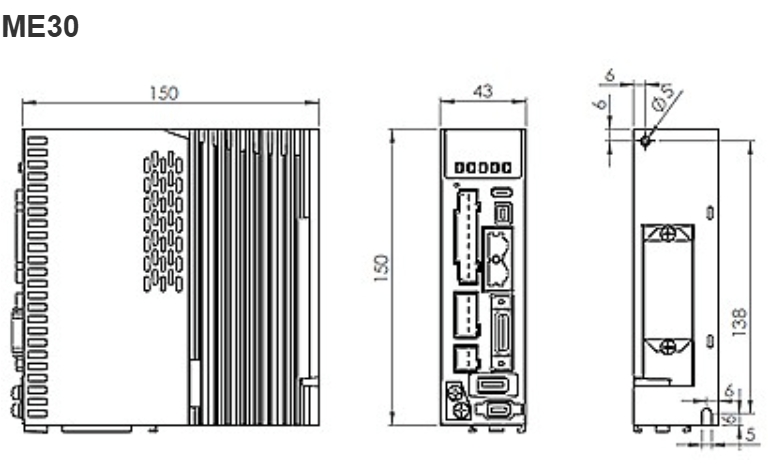

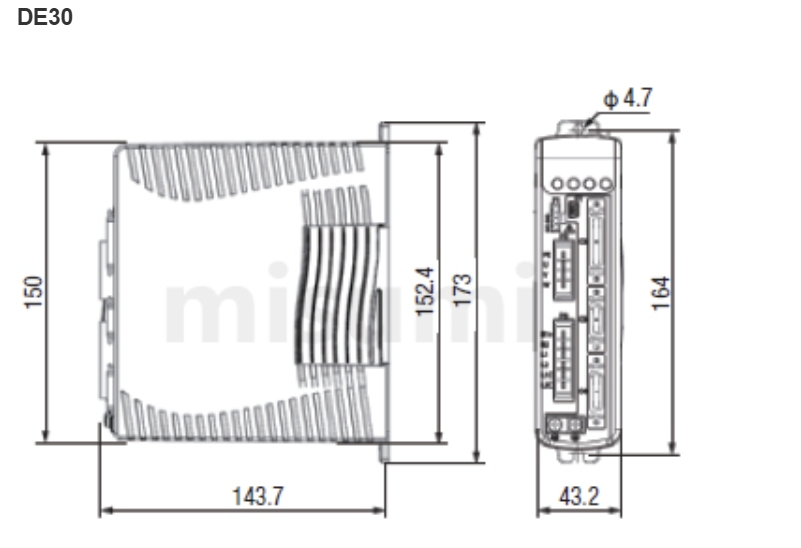

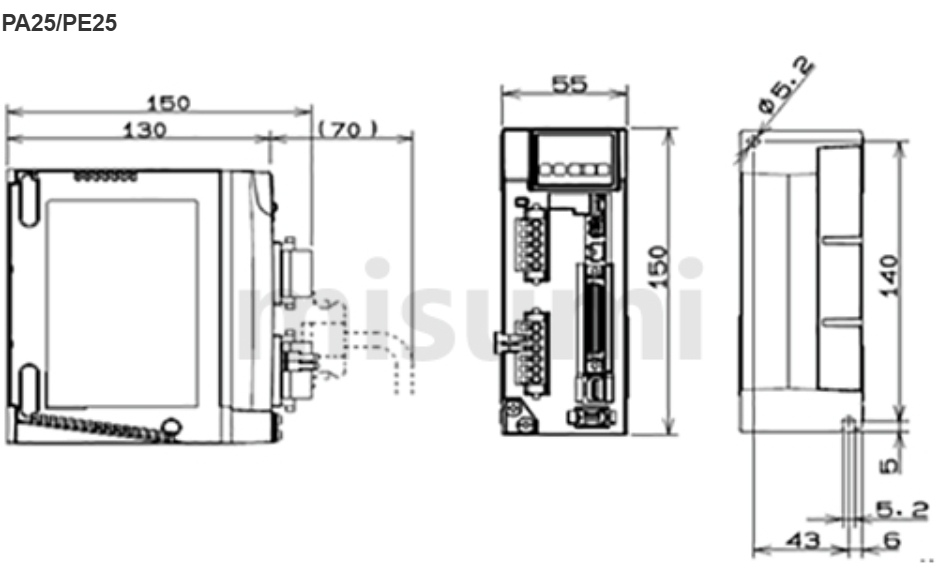

Driver Dimensional Drawing

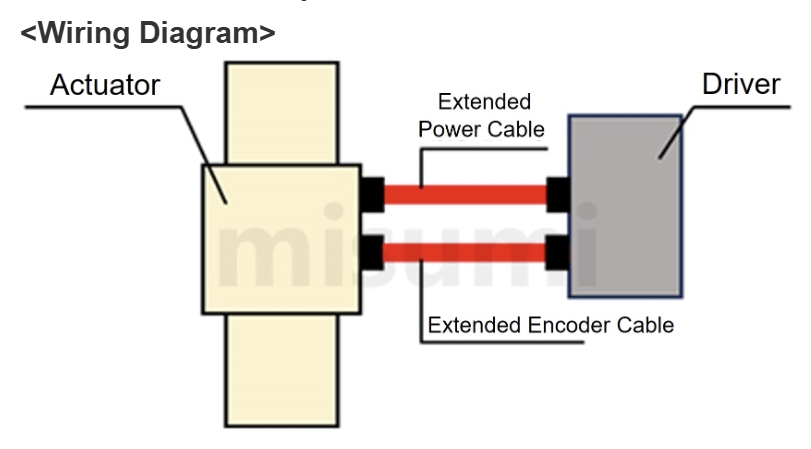

Extended Cable Specification

Driver wiring: please refer to the driver manufacturer’s official data (Panasonic, Servotronix).

Driver wiring: please refer to the driver manufacturer’s official data (Panasonic, Servotronix).

For the wiring diagram, please download and check the driver's manual

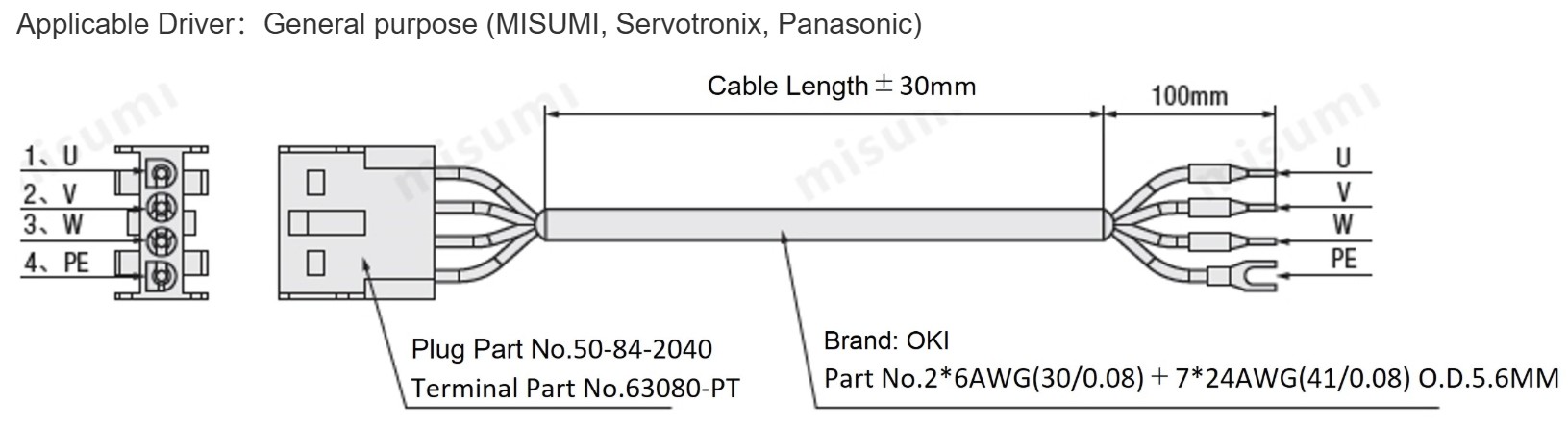

<Power Extension Cable>

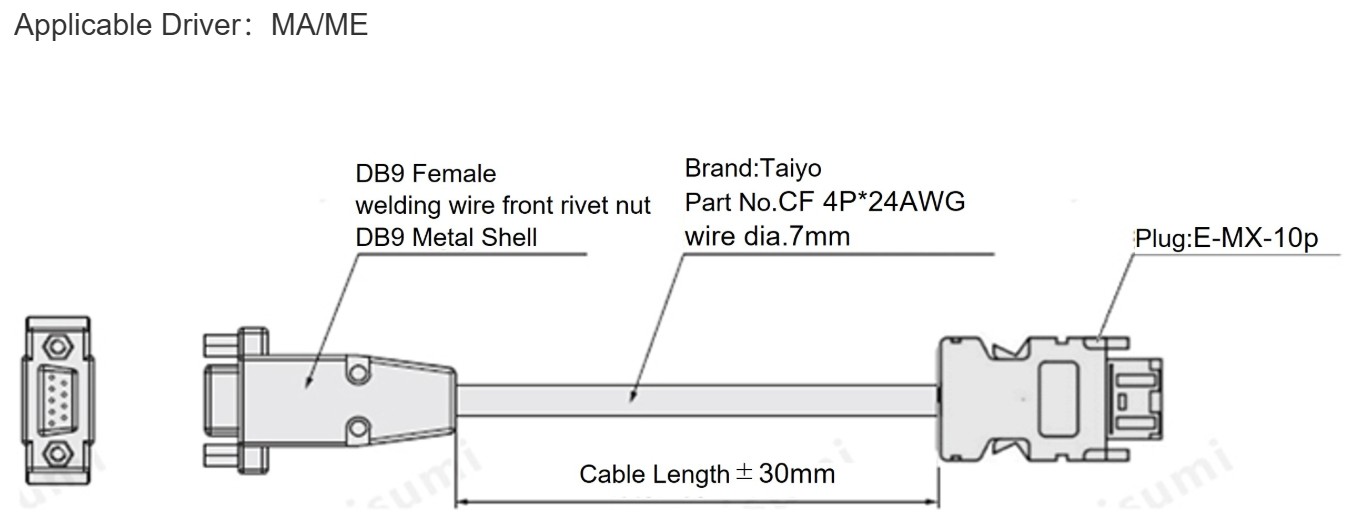

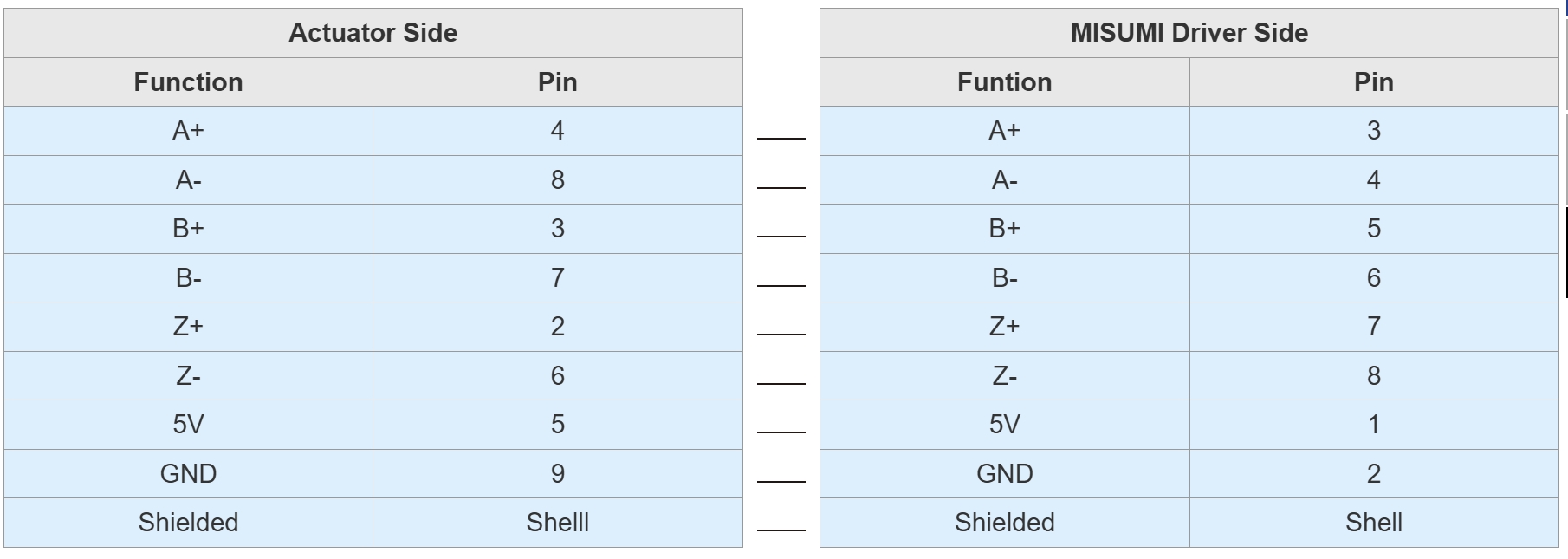

<Encoder extension cable for MISUMI Drivers>

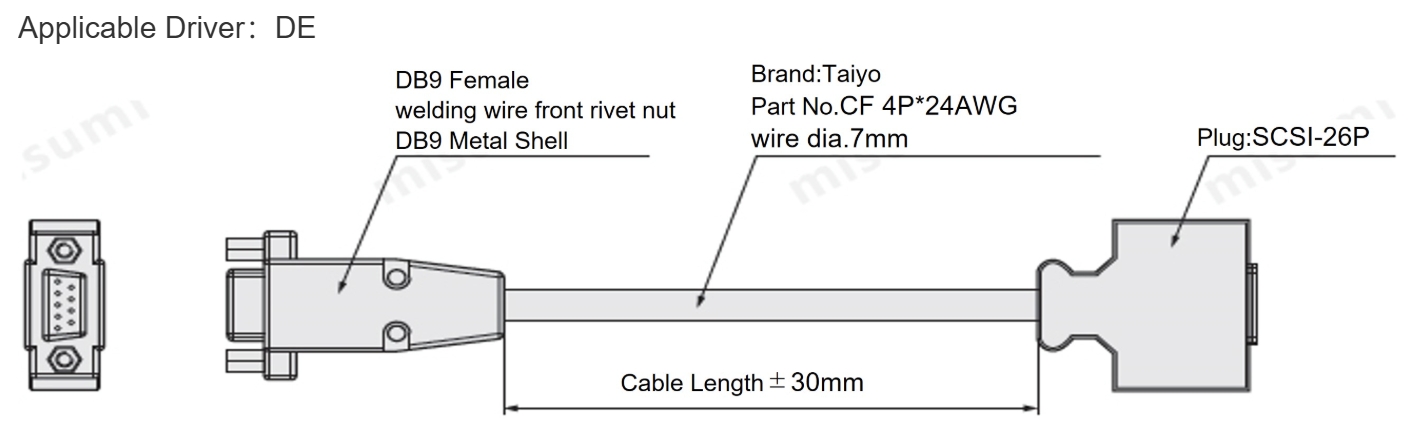

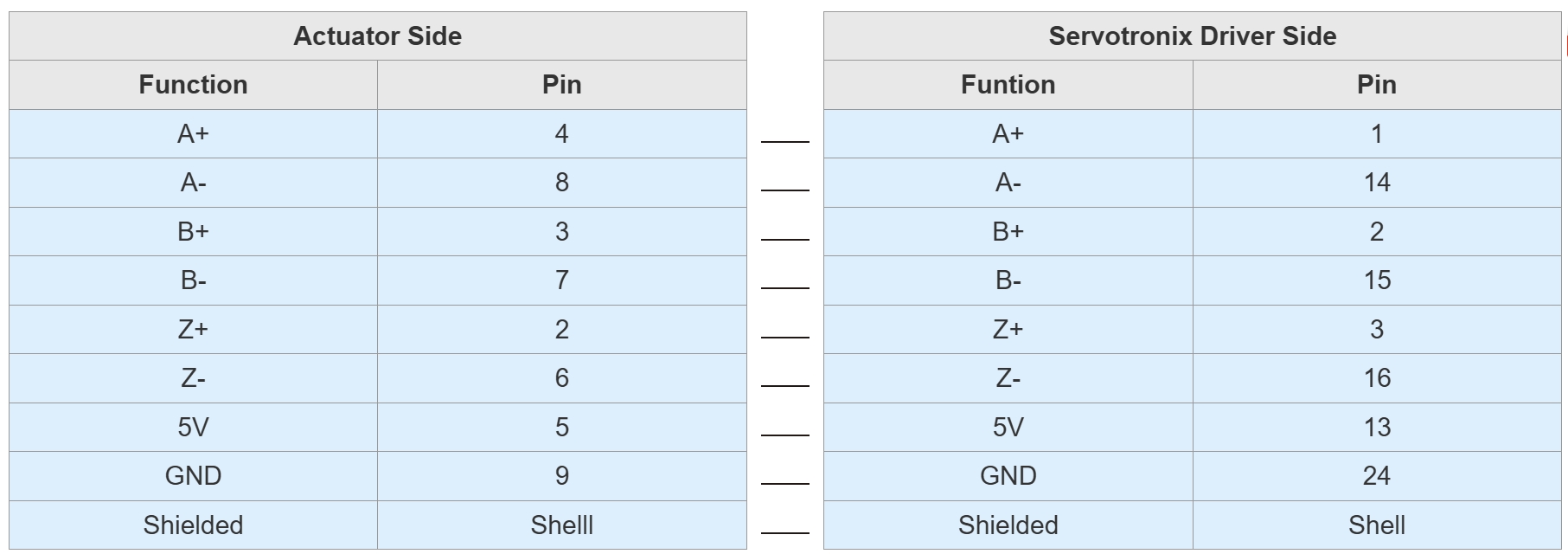

<Encoder extension cable for Servotronix Drivers>

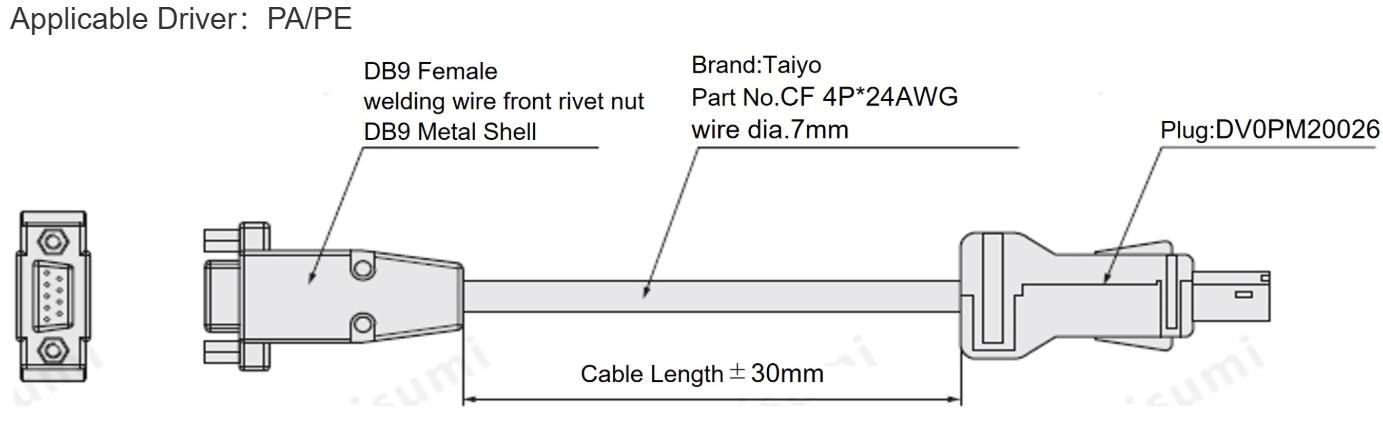

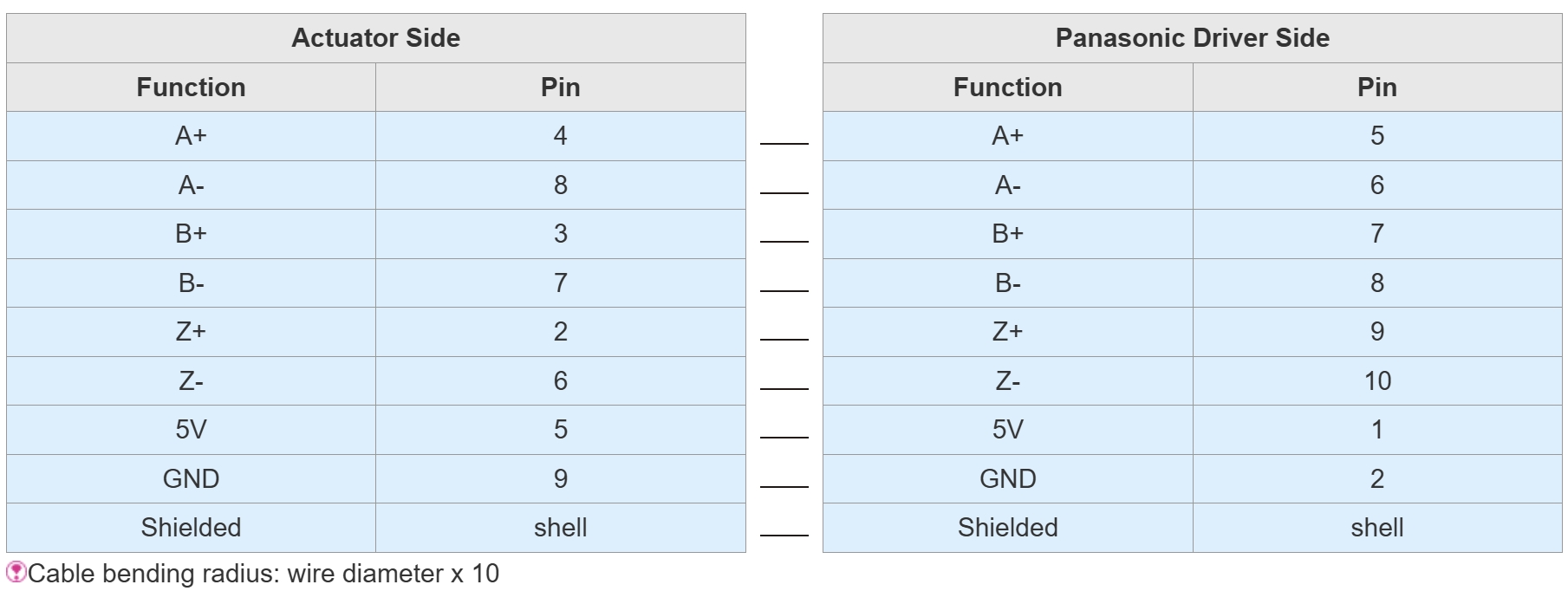

<Encoder extension cable for Panasonic Drivers>

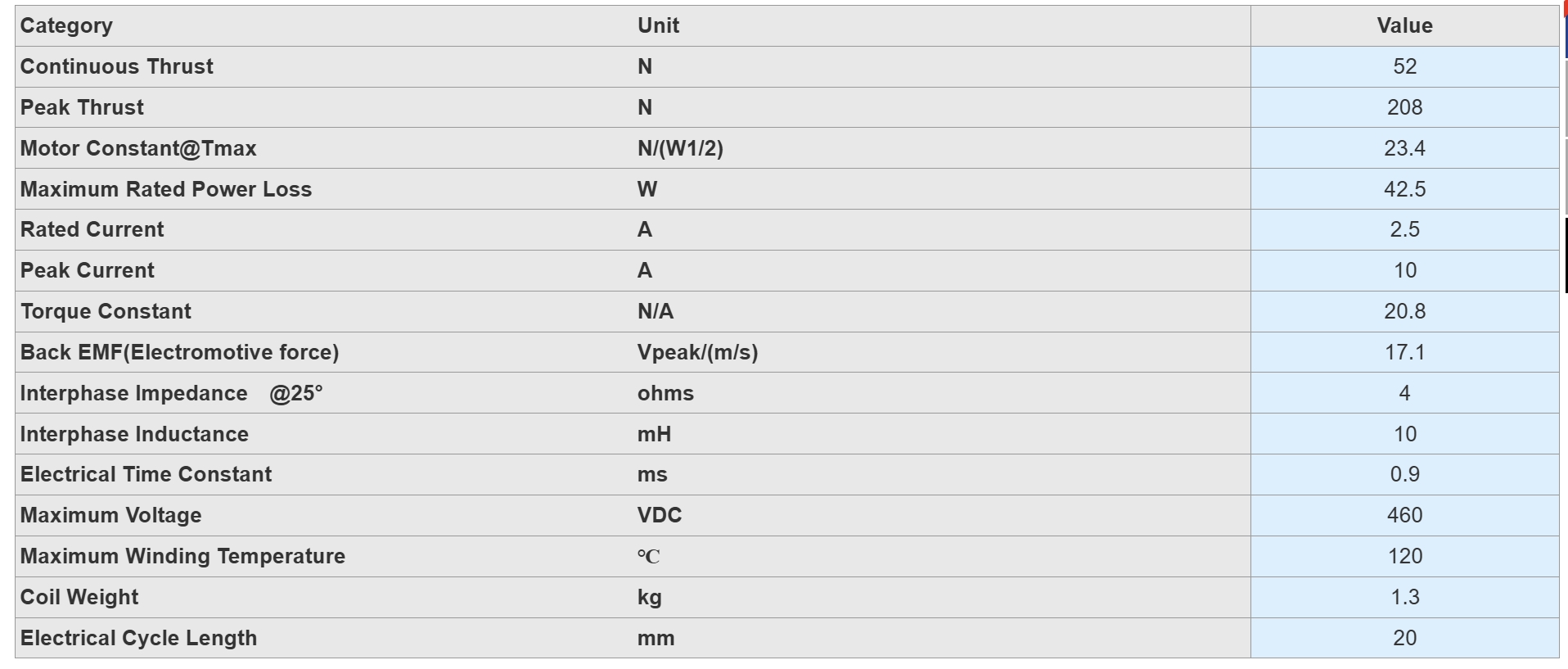

Motor Parameters

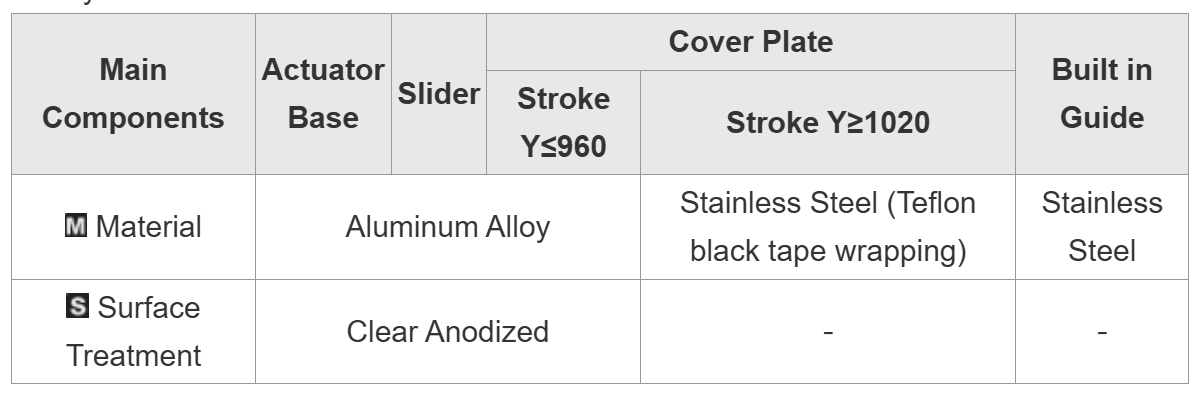

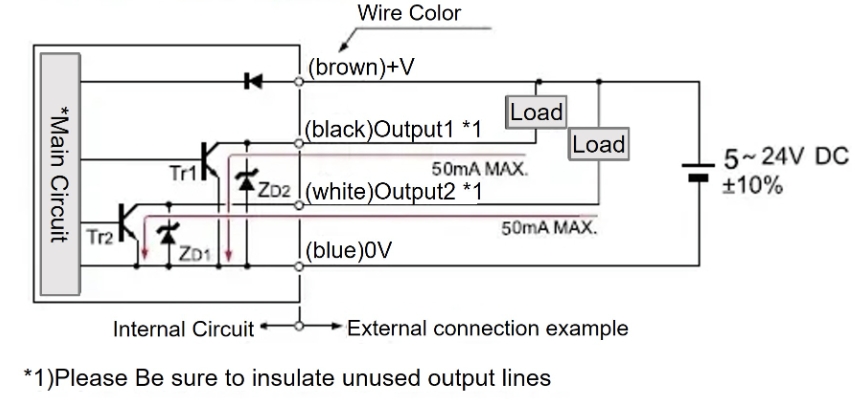

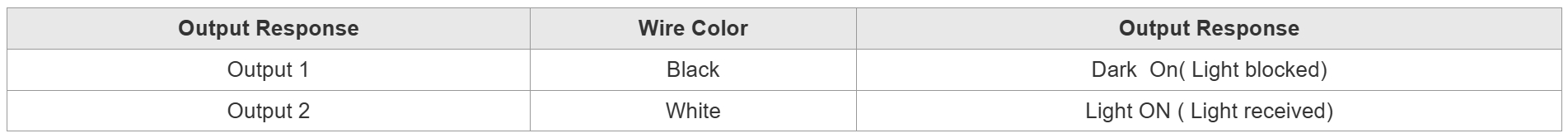

Attached Sensors

Precautions

- Operating Environment

- Linear Motor Actuators and Drivers may malfunction when used in harsh environments, so please use them in the following places.

- Indoor, ambient temperature is within the range of 0~40℃, ambient humidity is 10~80%RH with no freezing or no condensation.

- A place free of corrosive gases and flammable gases.

- A place where conductive powder such as iron powder, dust, oil mist, cutting fluid, moisture, salt and organic solvents are not scattered.

- A place without direct sunlight or radiant heat.

- A place where strong electric fields and strong magnetic fields will not be generated.

- A place where the main body will not be subject to vibration and impact.

- A place with an altitude below 1000m.

- A place convenient for inspection and cleaning.

- Safety Precautions

- This product is quite heavy. When transporting, please transport by two or more people or use tools according to the weight of the unit. Otherwise, injuries or product damage may occur.

- Please do not drop or knock this product

- Please do not disassemble the product without authorization, otherwise accuracy may deteriorate due to the intrusion of foreign objects. In addition, the driver may be charged and an electric shock may occur.

- The stator is a powerful magnet. Do not bring magnetic objects (especially metals) close to the magnet, otherwise your fingers may be caught between the magnet and the metal sheet due to the attraction of the magnet and be injured

- Persons using pacemakers must never approach the magnet.

- Please do not touch any moving parts while the power is on. In addition, do not approach the main body while the actuator is in operation or ready to operate.

- Other notes

- Payload of Linear Motor Actuators varies depending on the installation direction (horizontal or wall), as well as speed and acceleration/deceleration

- This product must not be used in vertical or sloped directions. Please ensure that the flatness of the installation base is within the range of ±0.01mm/300mm, otherwise it will affect the use

- Grease has been injected into the guide rail before this product leaves the factory. However, please inject new grease every 3 months after receiving the goods or every 500km of travel distance, otherwise it will affect the product life.

- This product comes standard with a magnetic encoder. Please be sure to keep away from magnetic objects (screwdrivers, etc.), otherwise it will affect use.

- This product does not guarantee the noise value during operation.

- When using the driver, be sure to read the driver manufacturer's instruction manual first to avoid damage caused by misoperation.

- Since the mechanical part of this product is a machined product, there will be knife marks and color differences in the appearance.

- It is normal for the product to have a few scratches or color changes as long as it does not affect the use and main functions.

- Because products are constantly being improved, the appearance and specifications of non-critical parts (provided that they do not affect use) may change without prior notice.