Prusament PA11 Carbon Fiber Black 800g (NFC)

About PA11 Carbon Fiber Black

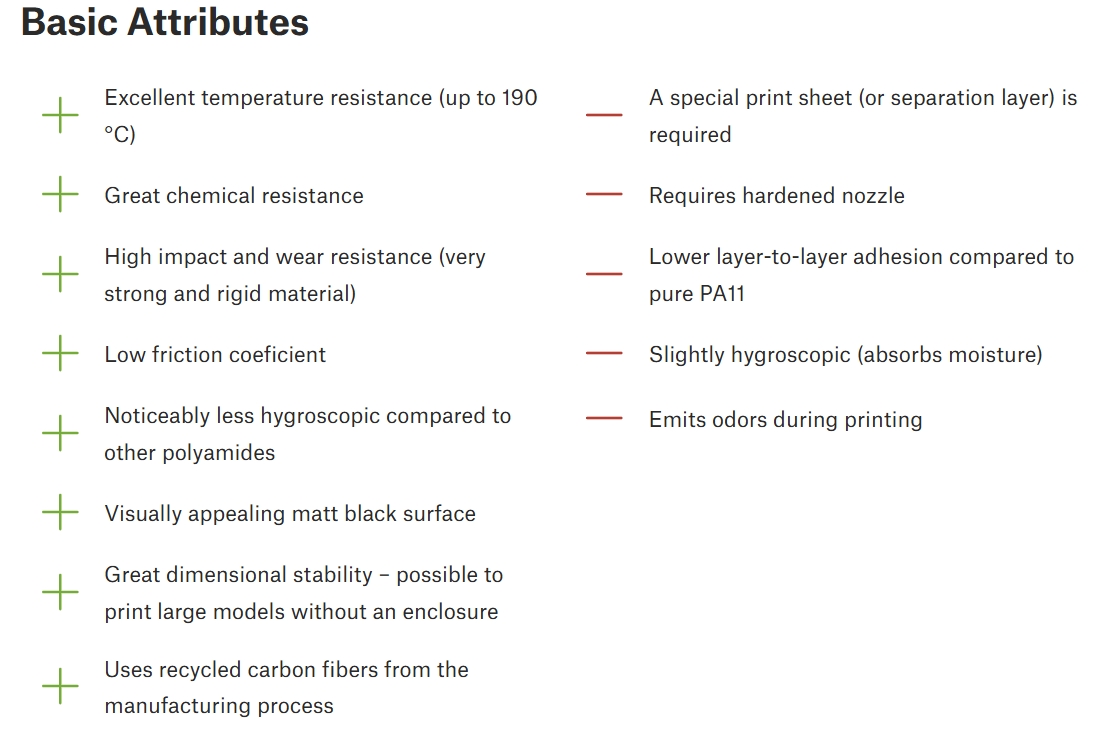

Prusament PA11 (Nylon) Carbon Fiber is an ideal filament for prototypes in the automotive, aerospace, and hobby industries, given its excellent resistance to heat, chemicals, and mechanical stress. Among the Prusament filaments, PA11-CF has by far the best temperature and chemical resistance. 3D-printed parts withstand up to 190 °C (depending on stress) and have increased resistance to many solvents (NaOH, Methanol, Ethanol, Toluene, Acetone, motor oils, benzene, diesel, etc.). PA11-CF is a material made from castor oil, the carbon fibers used for this material are recycled, the same as for the Prusament PC Blend Carbon Fiber. The best use of the PA11-CF is for making special chemically, mechanically, and heat-stressed parts, such as car engine components.

Printing Setup

| Nozzle | 285±10 °C |

| Heatbed | 110±10 °C |

| Recommended Steel Sheet | PA Nylon |

Before printing, learn about print surface preparation in our dedicated article and material table.

New spools equipped with OpenPrintTag

Prusament filaments are wound on a redesigned spool that introduces several improvements for an even better printing experience, starting in October 2025. The new spool features a simple locking mechanism that makes disassembly quick and easy, allowing effortless refills. It also stays secure during filament drying, even at higher temperatures. And with its slimmer dimensions, the spool ensures compatibility with a wide range of multi-color and multi-material printing systems.

Every new Prusament spool now comes with a fully rewritable NFC tag powered by the OpenPrintTag standard. It’s designed to work across brands and ecosystems. It is free to use, free to extend, and open for anyone to build upon. Most importantly, it works entirely offline. All essential data is stored directly on the tag. Your printer can recognize the spool instantly, with no dependence on cloud services or vendor lock-ins. The OpenPrintTag attached to your Prusament spool contains essential data about the material and can be read with the Prusa mobile app.

Beginners tips & tricks

It is necessary to use a hardened steel nozzle. Carbon fibers are a highly abrasive material and may damage brass nozzles.

Prusament PA11 Carbon Fiber Black can be printed onto textured or satin print sheets with a thin separation layer made with a glue stick (a separation layer is extremely important). However, the results may not be perfect. This is why we are introducing a new type of sheet - the Double-sided Powder-coated PA Nylon Satin Spring Steel Sheet which was designed specifically for Prusament PA11 Carbon Fiber Black.

If you are using the new PA Nylon Satin sheet, never clean it with IPA, acetone, or other solvents - the surface will deteriorate quickly. Instead, clean the sheet with water only (a drop of dishwashing detergent may be used to clean greasy areas).

We recommend printing in a well-ventilated room because PA11 with carbon fibers may release a noticeable odor into the air and produce ultra-fine particles. Printing on an enclosed 3D printer helps contain the odors and particles, plus the increased temperature may improve layer-to-layer adhesion.

PA11, like other polyamides, is a hygroscopic material (it absorbs air moisture). If the absorbed humidity reaches high values, the print quality will deteriorate. Deterioration occurs after a few days to a month, but if you are unsure or know you have not printed for a long time, we recommend drying the filament at 90°C for 4-6 hours before printing.

You can find more in-depth printing tips in our article at blog.prusa3d.com and in our Material table.

Notes

Prusament PA11 Carbon Fiber Black is made in-house by Prusa Research.

1.75 mm filament is manufactured with a precision of ±0.04 mm.

Carbon fibers inside the filament are made by recycling waste from the manufacturing process or from carbon composites after the end of their lifespan.

To dry the filament, please follow the instructions in our article.